Introduction

Safety caps HPLC systems are essential components that play a critical role in ensuring laboratory safety and preventing contamination of samples or solvents. These caps are specifically designed to securely seal the openings of HPLC solvent bottles, minimizing the risk of spills or leaks during operation. By effectively sealing the solvent reservoirs, safety caps HPLC help maintain the integrity of the HPLC system and preserve the quality of analytical results. Additionally, these caps provide an additional layer of protection against potential chemical exposure or evaporation, thereby enhancing overall laboratory safety practices. Investing in high-quality safety caps HPLC systems is a proactive measure that laboratories can take to promote a safe working environment and uphold stringent quality control standards.

In the realm of analytical chemistry, where precision is paramount, the role of safety caps in High-Performance Liquid Chromatography (HPLC) cannot be overstated. The use of these safety caps is not just about preventing spills; it is an integral part of maintaining the integrity of the experimental process. Laboratories that prioritize safety caps often observe a marked improvement in their overall workflow efficiency. For instance, consider a laboratory that handles volatile solvents. Without safety caps, the risk of solvent evaporation increases significantly, leading to inconsistencies that can compromise research outcomes. Therefore, the adoption of safety caps should be viewed as a foundational best practice in laboratory operations.

What Are Safety Caps for HPLC?

These caps are engineered to provide not only a physical barrier but also to facilitate optimal laboratory conditions through various innovative designs. For example, some safety caps incorporate advanced materials that can withstand extreme temperatures, making them suitable for a broader range of applications, including those involving harsh solvents or reagents. Furthermore, the design of safety caps has evolved to include ergonomic features that enhance user experience, ensuring that technicians can securely fasten and unfasten them without the risk of spills.

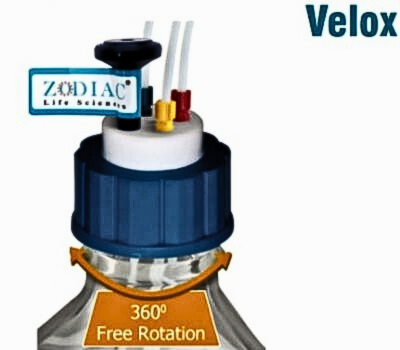

Safety caps are specialized sealing devices designed for solvent reservoirs in HPLC systems. They act as a barrier against airborne contaminants while allowing controlled airflow to prevent pressure buildup. Safety caps typically feature:

- Integrated filters to block dust and particulates.

- One-way check valves to prevent backflow and contamination.

- Multiple ports to accommodate different tubing connections.

- Chemical-resistant materials for durability and compatibility with aggressive solvents.

Importance of Safety Caps in HPLC

1. Prevention of Solvent Evaporation

Solvent loss due to evaporation can lead to inconsistent results and unnecessary reagent costs. Safety caps minimize solvent exposure to air, maintaining accurate concentrations.

2. Reduction of Contamination Risk

Airborne particles and moisture can alter the composition of mobile phases, affecting chromatographic performance. Safety caps provide a sealed environment, reducing this risk.

For example, in a situation where a technician is conducting a series of sequential tests requiring volatile solvents, the use of high-quality safety caps can significantly mitigate solvent loss. Laboratories that have implemented safety caps have reported a decrease in reagent costs by up to 20%, demonstrating the financial benefits alongside the safety improvements.

3. Enhanced Laboratory Safety

Moreover, contamination can stem not only from airborne particles but also from improper handling and storage of solvents. Laboratories must recognize that the initial investment in safety caps can prevent costly experiments from going awry due to contamination. For example, a study indicated that by using safety caps, one laboratory reduced sample contamination events by 50%, showcasing the caps’ effectiveness in real-world scenarios.

Many solvents used in HPLC are volatile and hazardous. Safety caps limit exposure to harmful fumes, improving air quality and reducing health risks.

A critical aspect of laboratory safety is the inhalation risk associated with volatile solvents. Research has shown that prolonged exposure to these chemicals can lead to serious health issues for laboratory personnel. By using safety caps, laboratories can significantly reduce the volatility of the working environment. For instance, a laboratory specializing in organic chemistry reported that implementing safety caps improved air quality measurements, leading to a healthier workspace and reduced sick leave among staff.

4. Consistent Analytical Performance

Consistency in analytical performance is crucial for any research. Safety caps contribute to this by creating a stable environment for the solvents. For example, a laboratory that regularly conducts high-stakes testing found that their results became more reproducible after integrating safety caps into their process. This consistency not only builds confidence in research results but also ensures compliance with regulatory standards.

Fluctuations in solvent composition can lead to variations in retention time and peak shape. Using safety caps helps maintain stability, ensuring reliable results.

Laboratories should also consider the potential for future expansion of their HPLC systems. Choosing safety caps that offer versatility and adaptability can save time and resources in the long run. For example, a lab that once struggled with cap compatibility during a system upgrade found that investing in multi-port caps allowed them to easily integrate new solvent lines, enhancing their operational flexibility.

How to Choose the Right Safety Caps for HPLC

In addition to compatibility with solvents, the choice of caps can also affect the overall efficiency of the HPLC system. For example, using poorly matched caps can lead to pressure issues, which can disrupt the flow of solvents and compromise results. Therefore, laboratories must be diligent in their selection process, ensuring that the caps they choose align with both their current and projected needs.

When selecting safety caps for your HPLC system, consider the following factors:

1. Compatibility with Solvents

Choose caps made from materials like PTFE, polypropylene, or PFA, which resist degradation from strong acids, bases, and organic solvents.

Moreover, the implications of filter efficiency extend beyond just preventing contamination; they also affect the longevity of the HPLC system itself. High-efficiency filters can protect sensitive components from damage caused by particulates, ultimately leading to lower maintenance costs and extended equipment life. Laboratories need to weigh the upfront costs against potential savings from reduced maintenance and downtime.

2. Number of Ports

As an illustration, a facility that experienced frequent pressure fluctuations in their HPLC system found that switching to caps with integrated pressure relief valves not only stabilized their processes but also enhanced the reliability of their results, preventing costly downtime due to pressure-related issues.

Select caps with an adequate number of ports to accommodate multiple solvent lines, waste lines, and air filters as needed.

3. Filter Efficiency

Look for caps with high-efficiency filters (0.2 µm or smaller) to prevent contamination from particles and dust.

In summary, the strategic selection and implementation of safety caps in HPLC systems are essential for optimizing laboratory operations. These caps not only safeguard against contamination and evaporation but also promote a culture of safety and reliability. Laboratories that prioritize these components as part of their standard operating procedures set themselves up for success. With ongoing advancements in cap technology and materials, it is vital for laboratories to stay informed and proactive in their choices, ensuring that they continue to protect their personnel and their research outcomes.

4. Pressure Control Features

Safety caps with integrated pressure relief valves ensure stable solvent flow without causing backflow or system blockages.

5. Sealing Efficiency

Ensure the cap forms a tight seal to prevent leaks and evaporation, reducing solvent consumption and exposure.

Conclusion

Safety Caps HPLC are essential components for maintaining solvent integrity, preventing contamination, and ensuring a safe laboratory environment. By selecting the right safety caps, laboratories can improve analytical accuracy, enhance safety protocols, and minimize solvent waste. Investing in high-quality safety caps is a simple yet effective way to optimize HPLC performance and extend the lifespan of your analytical system.